Belimo Energy Valve™ in Chilled Beam applications

O que é uma Viga fria?

Uma viga fria é um tipo de sistema AVAC de convecção projetado para aquecer e resfriar espaços, normalmente implantado em edifícios de escritórios sem divisórias. Os tubos passam por um trocador de calor, diretamente integrados a um teto suspenso ou pendurados abaixo do teto suspenso de um ambiente.

Há dois tipos de vigas frias em uso hoje em dia:

- Um feixe passivo resfria o ar ao seu redor, formando uma corrente de convecção natural onde o ar resfriado cai e o ar mais quente sobe para substituí-lo, resfriando assim o espaço.

- As vigas frias ativas também são amplamente usados e utilizam o ar de uma AHU para induzir um fluxo de ar adicional no feixe.

O principal desafio com esta aplicação é o controle da temperatura e da vazão da água, garantindo que a temperatura da superfície do feixe não caia abaixo do ponto de orvalho do espaço.

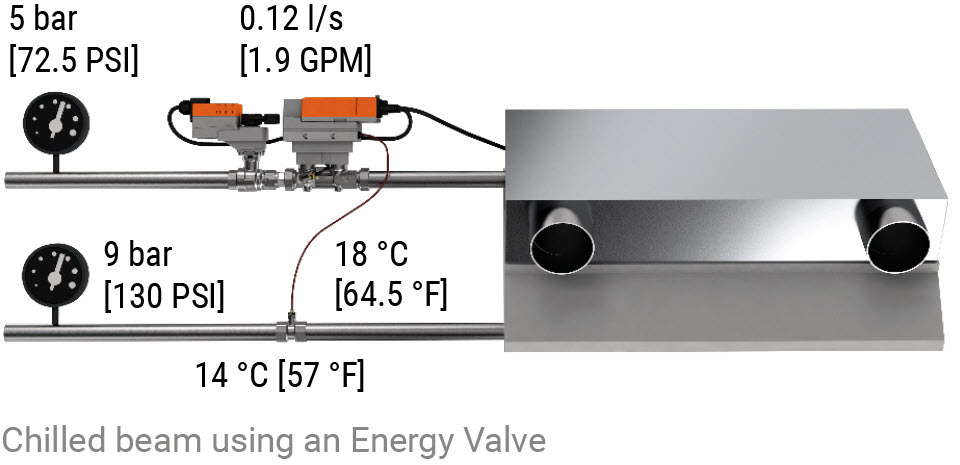

Esquemático

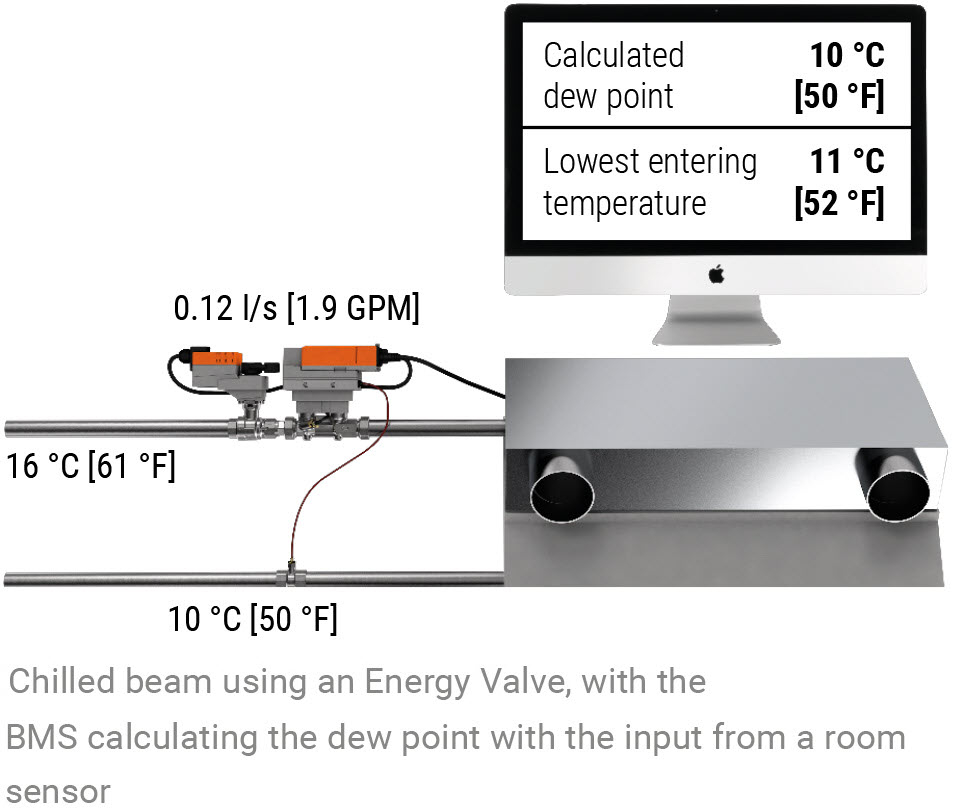

A imagem mostra o esquemático de uma aplicação de viga fria utilizando uma Energy Valve. Isto oferece a seguinte funcionalidade de controle:

- Medição exata do fluxo volumétrico e da temperatura de alimentação e retorno

- Monitoramento e controle da potência térmica da unidade

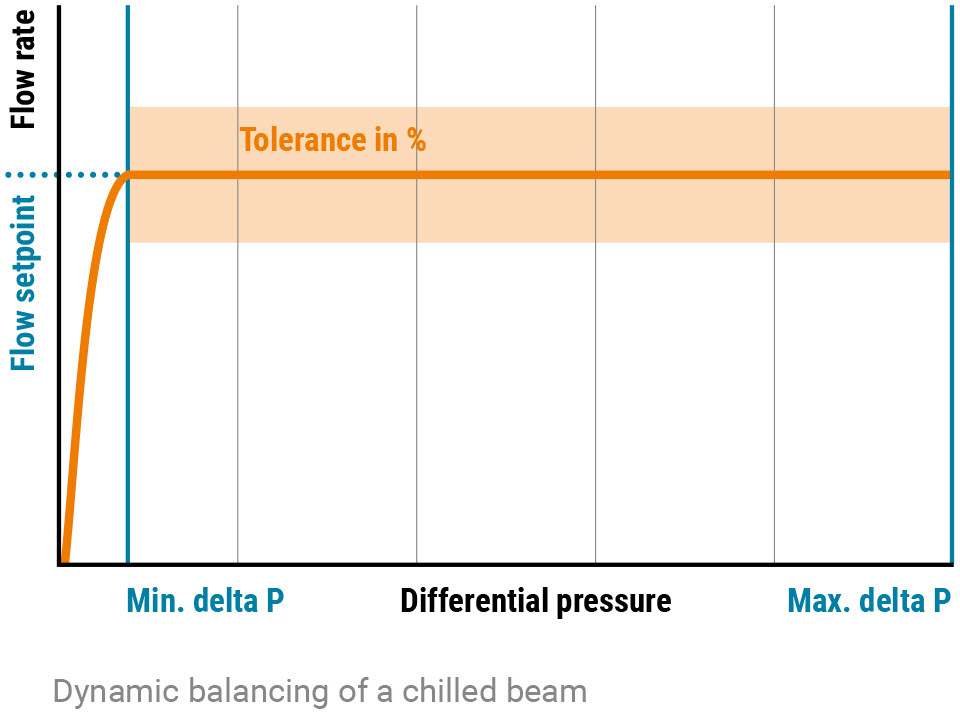

- Balanceamento hidrônico permanente da vazão a pressões variáveis do sistema e em qualquer condição de carga

- Integração opcional de um interruptor de sensor de ponto de orvalho

- O diferencial de temperatura necessário em feixes frios é muito baixo, fazendo com que o gerenciamento seja essencial

Order the new Belimo Energy Valve™ now

Learn how the Energy Valve improves your chilled beam

Situações comuns em aplicações de vigas frias e por que você deve escolher a Energy Valve™ da Belimo

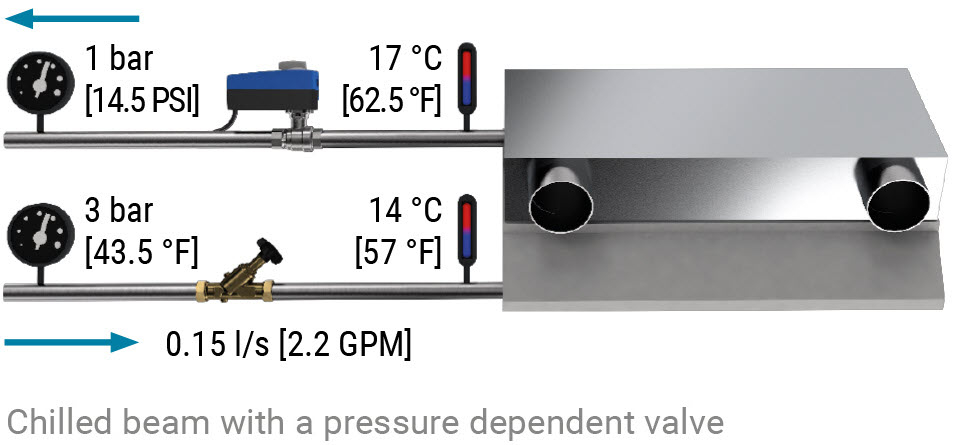

Low water temperatures and insufficient humidity control can lead to condensate forming on the chilled beam, and can subsequently damage furniture of office equipment that can be costly. However, conservative supply water temperatures can result in insufficient cooling capacity.

Using the more accurate and responsive immersion flow sensor from the Belimo Energy Valve™, DDC systems are able to detect and close-off water flows before condensate forms on the chilled beams. Reliable data from both the space and the water temperatures is the key to maximising chilled beam performance, while minimising the risk of condensate forming. An outdoor humidity/temperature sensor, such as the Belimo 22UTH-11, can be used to measure the outdoor air conditions and to adapt the AHU-control accordingly.

Supply air into the occupied space, and the circulated air from the room, pass over the coils of the chilled beam. The indoor dew point must be maintained below the surface temperature of the chilled beam coil to prevent condensation water dropping from the ceiling.

The primary air system in the AHU is used to offset the space latent load, and it typically maintains the indoor dew point at or below 13 °C [55 °F] to prevent condensation. Also, the water temperature delivered to the beams is typically maintained between 14 °C [58 °F] and 16 °C [60 °F], sufficiently above the dew point of the space.

Dica profissional

Consulte as normas locais sobre os valores recomendados de temperatura e umidade do ar ambiente (ou valores máximos), assim como as temperaturas recomendadas da água de resfriamento. Se você tiver cargas de refrigeração menores no ambiente ou grandes superfícies de resfriamento, é possível aumentar as temperaturas da água de resfriamento em alguns graus (por exemplo, até 18 °C). Ainda deve ser possível manter um resfriamento suficiente no ambiente, e assim a desumidificação pode ser realizada de forma a economizar energia.

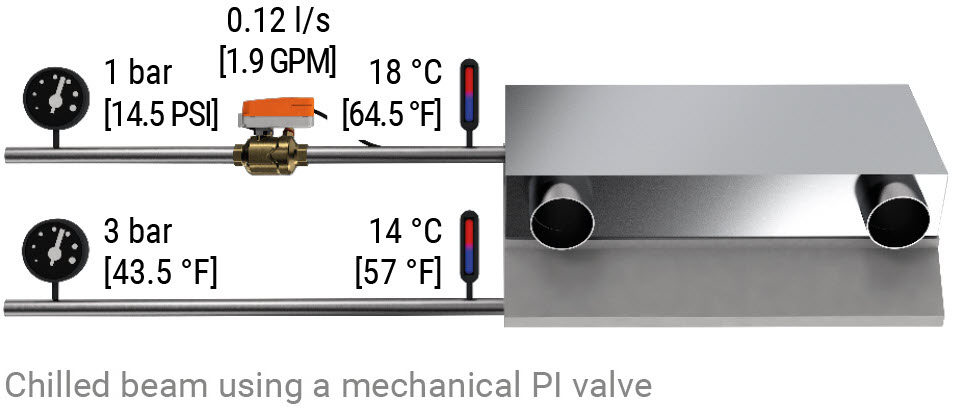

Exemplo de aplicação

The Energy Valve will keep the flow as designed regardless of pressure fluctuations, at 0.12 l/s [1.9 GPM]. It will also manage the delta T over the coil and provide all essential data regarding flow, temperatures and energy to the BMS. Using the data available from the EV, many other value-added features are available, such as early detection of likely condensate issues.

As shown below, the Energy Valve is on the same network as the sensor and the BMS head-end PC. The BMS is looking at the water flow temperature and calculating the dew point, using the RH and temperature data from the room unit. The BMS has seen the entering water temperature is at dew point, and has commanded the valve to close, in order to prevent condensate forming on the unit. The Delta T manager will keep your beams optimized when air flows over the coil vary.