Belimo Energy Valve™ in Chilled Beam applications

¿Qué es una viga fría?

Una viga fría es un tipo de sistema de convección de HVAC diseñado para calentar y enfriar ambientes, normalmente implementado en edificios de oficinas de planta abierta. Los tubos pasan a través de una "viga" (un intercambiador de calor), ya sea directamente integrada en el techo suspendido, o colgada bajo el techo suspendido de una sala.

Actualmente se utilizan dos tipos de vigas frías:

- Una viga pasiva enfría el aire a su alrededor y forma una corriente de convección natural en la que el aire enfriado cae y el aire calentado se eleva para sustituirlo, enfriando así el ambiente.

- Las vigas frías activas también se usan de forma común y utilizan el aire de una unidad manejadora de aire para inducir un flujo de aire adicional sobre la viga.

El principal desafío de esta aplicación es el control de la temperatura del agua y el flujo, garantizando que la temperatura superficial de la viga no caiga por debajo del punto de rocío del ambiente.

Esquema

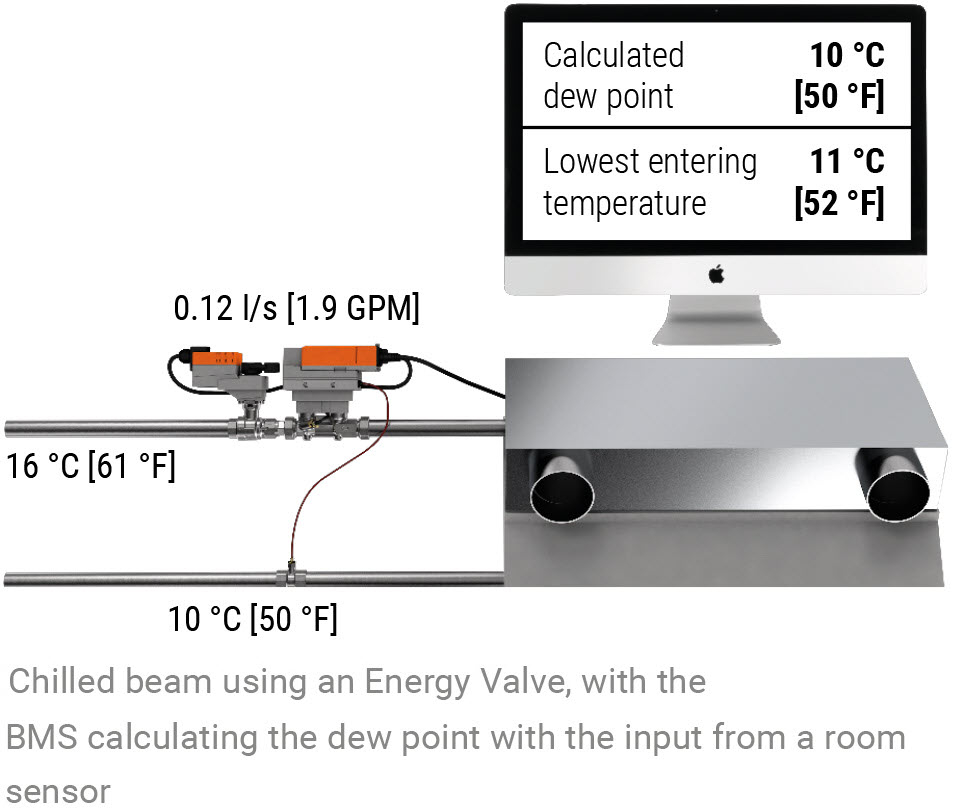

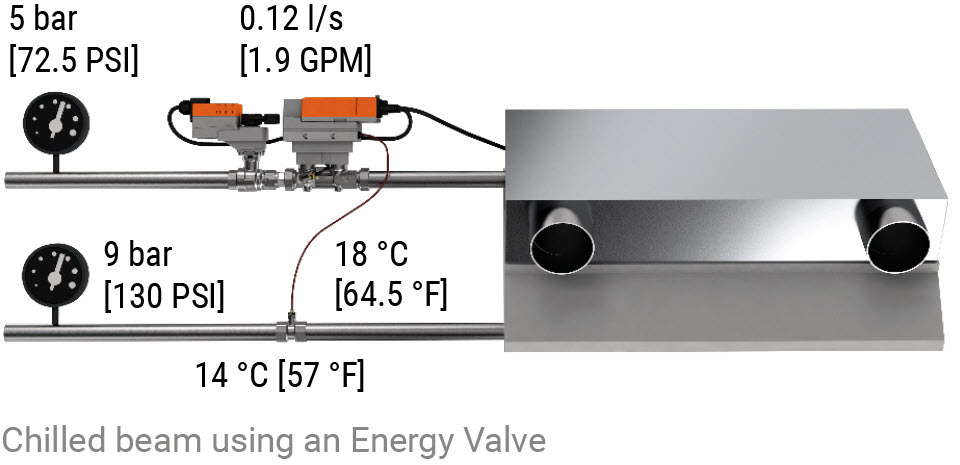

La imagen muestra el diagrama de una aplicación de viga fría con una Energy Valve. Esto proporciona la siguiente funcionalidad de control:

- Medición precisa del flujo y la temperatura de alimentación y retorno

- Monitoreo y control de la potencia térmica de la unidad

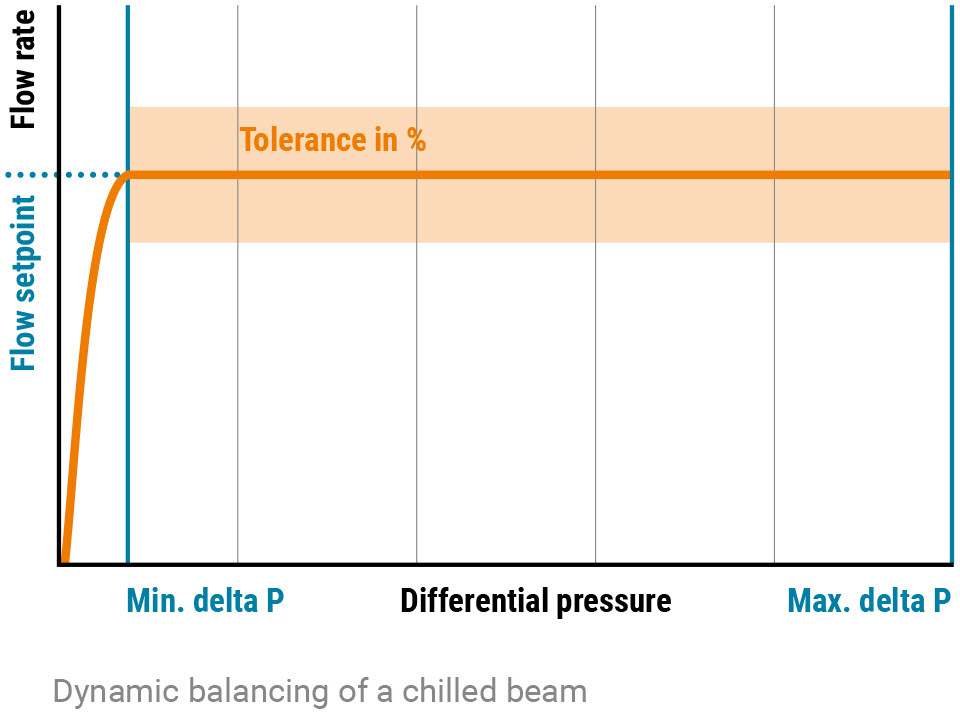

- Balanceo hidrónico permanente del flujo de agua con cambios en la presión del sistema y con cualquier condición de carga

- Integración opcional de un interruptor que sensa el punto de rocío

- El diferencial de temperatura necesario en las vigas frías es muy bajo, lo que hace que su control resulte esencial

Order the new Belimo Energy Valve™ now

Learn how the Energy Valve improves your chilled beam

Problemas comunes en aplicaciones de viga fría y por qué debería elegir la Belimo Energy Valve™

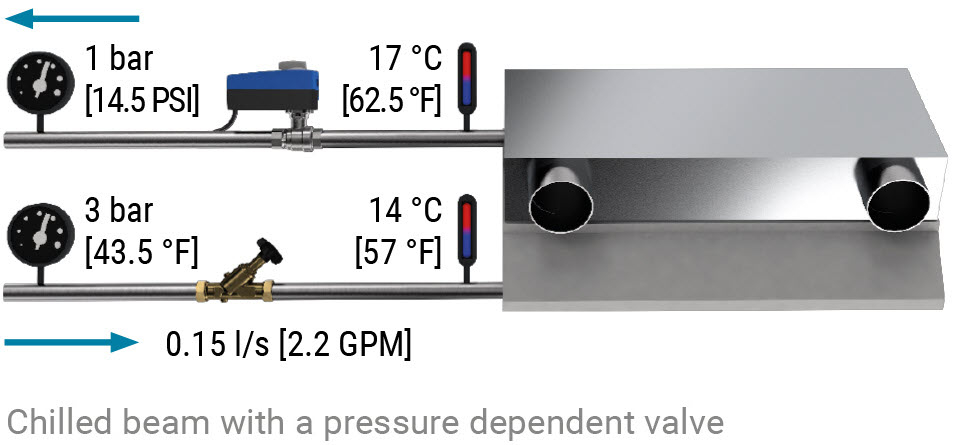

Low water temperatures and insufficient humidity control can lead to condensate forming on the chilled beam, and can subsequently damage furniture of office equipment that can be costly. However, conservative supply water temperatures can result in insufficient cooling capacity.

Using the more accurate and responsive immersion flow sensor from the Belimo Energy Valve™, DDC systems are able to detect and close-off water flows before condensate forms on the chilled beams. Reliable data from both the space and the water temperatures is the key to maximising chilled beam performance, while minimising the risk of condensate forming. An outdoor humidity/temperature sensor, such as the Belimo 22UTH-11, can be used to measure the outdoor air conditions and to adapt the AHU-control accordingly.

Supply air into the occupied space, and the circulated air from the room, pass over the coils of the chilled beam. The indoor dew point must be maintained below the surface temperature of the chilled beam coil to prevent condensation water dropping from the ceiling.

The primary air system in the AHU is used to offset the space latent load, and it typically maintains the indoor dew point at or below 13 °C [55 °F] to prevent condensation. Also, the water temperature delivered to the beams is typically maintained between 14 °C [58 °F] and 16 °C [60 °F], sufficiently above the dew point of the space.

Consejo profesional

Consulte los estándares locales relativos a las temperaturas de aire y valores de humedad ambiental recomendados (o los valores máximos), así como las temperaturas del agua de enfriamiento recomendadas. Si las cargas de enfriamiento en la sala o en grandes superficies de enfriamiento son menores, las temperaturas del agua helada pueden aumentarse algunos grados (por ejemplo, hasta 18 °C). Es posible mantenerse el enfriamiento suficiente en la sala y, adicionalmente, realizarse la deshumidificación con un método que ahorre energía.

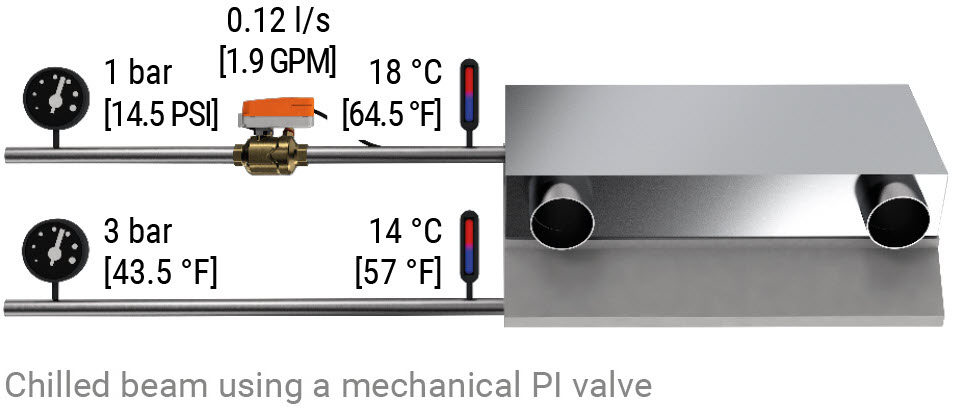

Ejemplo de aplicación

The Energy Valve will keep the flow as designed regardless of pressure fluctuations, at 0.12 l/s [1.9 GPM]. It will also manage the delta T over the coil and provide all essential data regarding flow, temperatures and energy to the BMS. Using the data available from the EV, many other value-added features are available, such as early detection of likely condensate issues.

As shown below, the Energy Valve is on the same network as the sensor and the BMS head-end PC. The BMS is looking at the water flow temperature and calculating the dew point, using the RH and temperature data from the room unit. The BMS has seen the entering water temperature is at dew point, and has commanded the valve to close, in order to prevent condensate forming on the unit. The Delta T manager will keep your beams optimized when air flows over the coil vary.